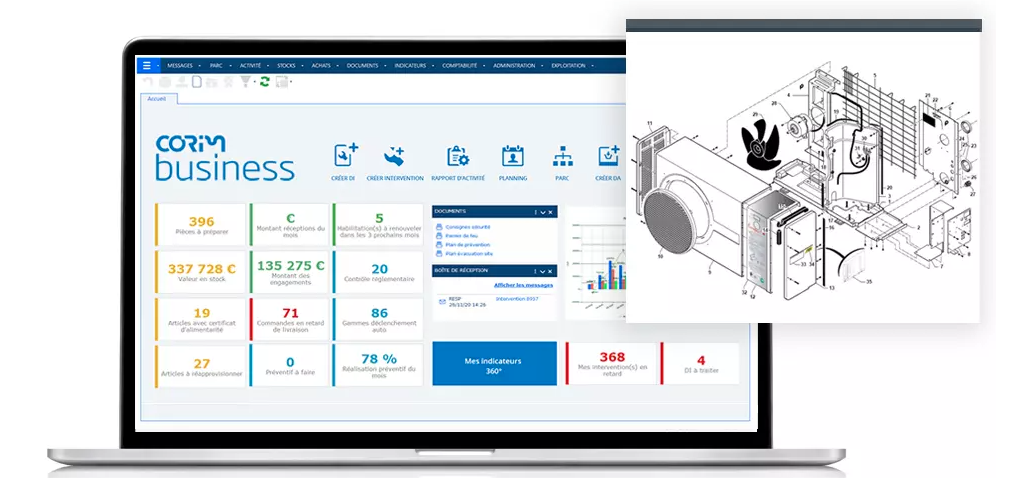

The main objective of a maintenance contract is to avoid costly production stoppages caused by equipment breakdowns, and all this at the lowest possible cost. Preventive maintenance is based on maintenance routines based on time intervals or operating hours that are done periodically. The manufacturer of the machine, with thousands of tests and units in the field, knows perfectly the life of the different pieces of equipment, and this gives us the starting point for the preventive of our machine.

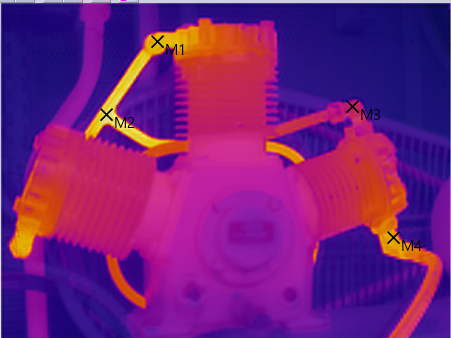

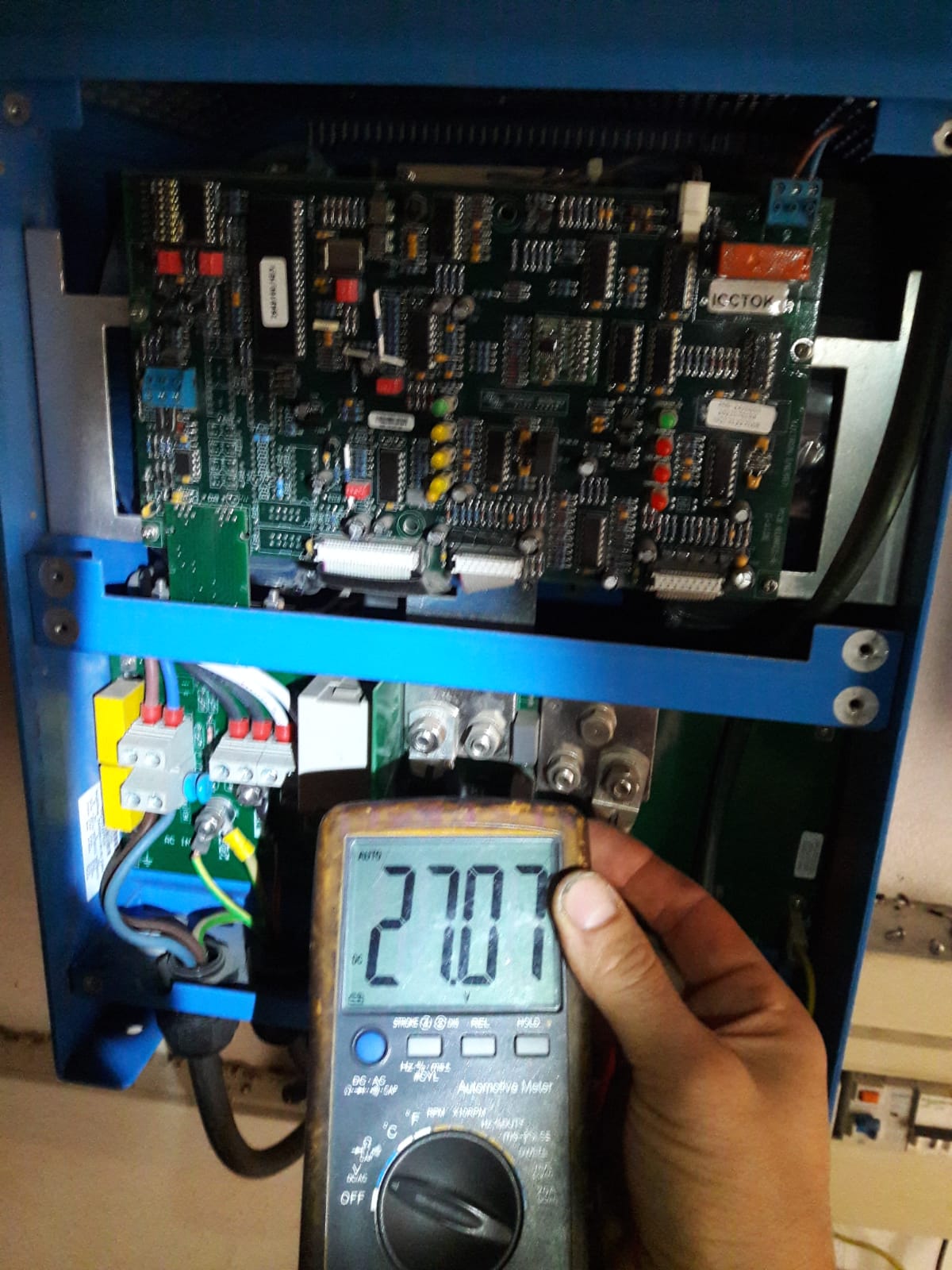

But we must not forget that each machine is unique and they work differently depending on the conditions of work demand, environment, ventilation, installation of the machine, electrical supply, etc…

For this reason it is necessary to adjust these manufacturer’s recommendations to the machine in question, in order to adjust maintenance costs without neglecting the machine. There is only one objective way to recommend maintenance intervals for a compressor, with predictive maintenance.